V Swing World. First Story

LEGO

Founded in Denmark in 1932, LEGO, the world's largest toy brick manufacturer, was on the verge of bankruptcy at the turn of the millennium. Technology was also a game changer in the toy industry. In 1999, when the company celebrated 50 years of patenting the plastic LEGO toy brick, the future seemed dark. The new generation of children no longer wanted to play with the same colourful blocks as their parents.

LEGO struggled to cope with the changes by expanding its fields of activity and relying on making hit products based on film heroes. As it later turned out, it was just a patch, not a cure. Despite the efforts the company was at its biggest loss in the company's history in 2003 and 2004. The only way to escape bankruptcy was because of the owners' cash injections.

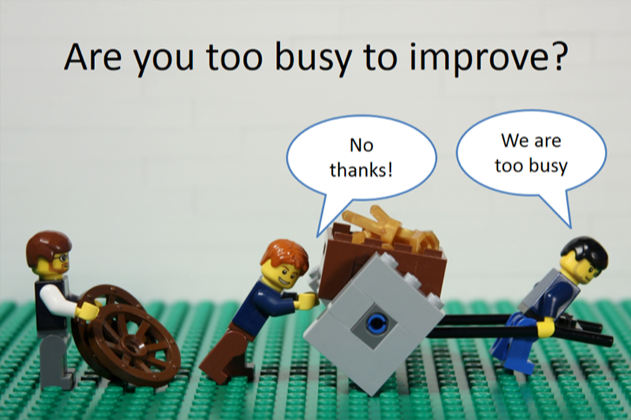

With the help of radical changes and layoffs, losses were stopped the following year. Two important steps were taken in 2006 to get out of the slump. First, LEGO started to introduce cost-effective thinking at its Danish factory, also known as “LEAN production”. Secondly, it was decided to outsource most of the production from the Flextronics factories in Mexico and the Czech Republic. According to the plan, 900 of the 1,200 employees at the Danish factory had to be made redundant after the successful transfer of production.

At first, it seemed that the decisions made would prove to be a lifeline for LEGO. In 2006, the company had a profit of more than EUR 170 million. But the management was unhappy. The new partner was constantly experiencing problems with quality assurance and management of large volumes of goods. In a long run, that would have meant damaging LEGO's reputation and brand. Although looking at profit figures everything was fine in the short term, the future was still very dark in the long term.

Luckily, the LEGO management's second decision had begun to pay off, with the opportunity to maintain competitiveness in the long term. Cost-efficient production had begun to pay off.

Human attitudes towards workers, while anticipating and supporting continuous development, are likely to be important factors why LEGO was able to rapidly deploy cost-effective production at its Danish factory and quickly achieve good results. By 2007, it was clear to LEGO management that the efficiency of the Danish factory could be increased to such an extent that production in Denmark would be profitable. The production was withdrawn from Flextronics and the quality and delivery problems were solved. The productivity of LEGO's Danish factory increased by 30% and the factory's 1,200 employees remained.

If LEGO had only limited itself to improving production, they would not have been able to turn their declining sales around. Getting out of the bottom of the hole also played an important role in making product development more systematic and involving distributors in product development.

LEAN means skinny, clammy in English. LEAN production began in the 1950s with the Japanese company Toyota, and the system was originally called TPS (Toyota Production System). The system was named LEAN by researchers at the Massachusetts Institute of Technology in 1990, and it spread around the world to various fields, being today one of the most serious business management systems in the world.

You can read more about LEAN management in the book "The Machine That Changed the World" written by James P. Womack, Daniel T. Jones, and Daniel Roos.